Dans toute opération de fabrication, le gaspillage de matériaux représente un coût important. Lors du bobinage de transformateurs, une seule erreur peut entraîner une quantité coûteuse de feuille gaspillée. Si vous utilisez une machine manuelle ou obsolète, vous produisez probablement un pourcentage élevé de pièces rebutées. Alors, comment une machine à bobiner la feuille de transformateur peut-elle réduire votre gaspillage de matériaux et augmenter votre rentabilité ?

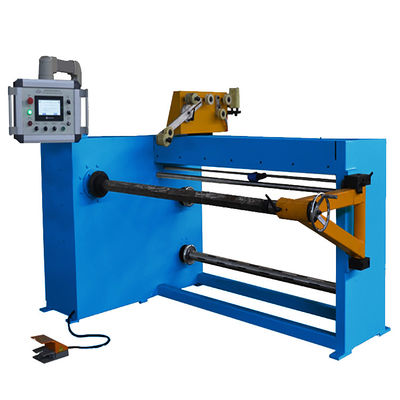

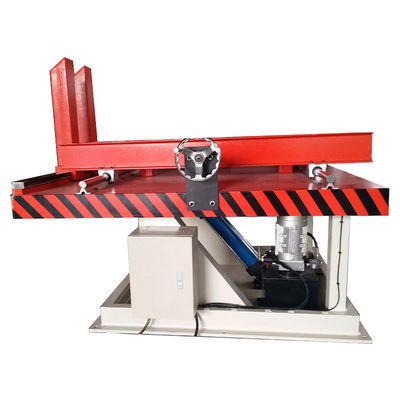

Nos machines sont conçues pour optimiser le processus de bobinage et minimiser le gaspillage à chaque étape. Le système contrôlé par ordinateur garantit que chaque bobinage est parfaitement précis, ce qui élimine le besoin de retouches et la création de pièces rebutées.

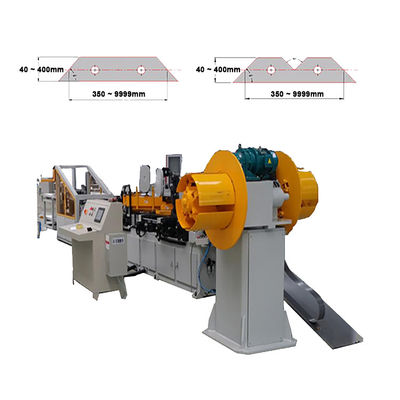

Contrôle précis : La machine contrôle avec précision la longueur de la feuille et le nombre de bobinages, ce qui vous assure de n'utiliser que le matériau dont vous avez besoin.

Élimine les erreurs humaines : Le processus automatisé élimine le risque d'erreur humaine, qui est une source majeure de gaspillage de matériaux.

Minimise les défauts : La précision et la constance de la machine réduisent le nombre de bobines défectueuses, ce qui réduit à son tour la quantité de feuille et d'autres matériaux gaspillés.

Utilisation efficace des matériaux : Nos machines peuvent optimiser le processus de bobinage pour utiliser la feuille aussi efficacement que possible, ce qui vous aide à tirer le meilleur parti de chaque rouleau.

En investissant dans une machine à bobiner la feuille de transformateur, vous n'améliorez pas seulement votre efficacité ; vous prenez également une décision financière judicieuse qui réduira votre gaspillage de matériaux et augmentera votre rentabilité.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!