Dans toute opération de fabrication, le retraitement et l'inspection sont une source majeure de perte de temps et d'argent.ce qui augmente vos coûts de main-d'œuvre et votre temps de productionAlors, une machine peut-elle vous aider à réduire votre temps de retouche et d'inspection?

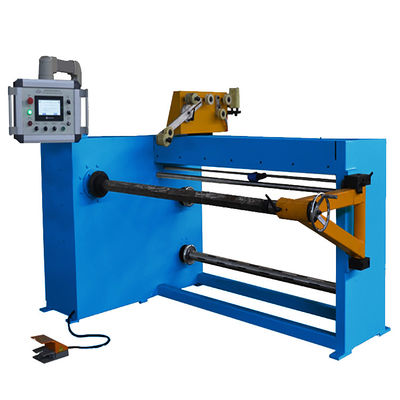

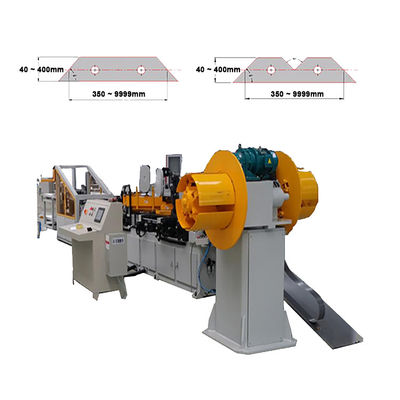

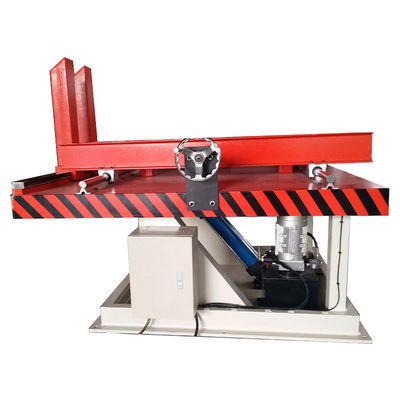

Notre machine à enrouler les feuilles de transformateur est une solution fiable qui peut vous aider à réduire votre temps de retouche et d'inspection et à augmenter votre rentabilité.

Précision de la première partie: La précision de nos machines garantit que la première bobine produite est précise, ce qui élimine le besoin de retravailler et économise beaucoup de temps.

Qualité constante: La répétabilité de nos machines garantit que chaque bobine est fabriquée selon les mêmes spécifications, ce qui réduit le besoin d'inspections fréquentes.

Surveillance en temps réel: La machine est équipée d'une surveillance en temps réel qui peut détecter tout problème potentiel pendant le processus d'enroulement, ce qui empêche la production de bobines défectueuses.

Réduction de la main-d'œuvre: En réduisant le besoin de retravail et d'inspection, vous pouvez réaffecter votre personnel à des tâches plus productives, ce qui réduit vos coûts de main-d'œuvre et augmente votre rentabilité.

En choisissant une machine de remontage de feuille transformatrice, vous n'améliorez pas seulement votre efficacité; vous simplifiez également votre flux de travail pour une rentabilité maximale.

Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!  Votre message doit contenir entre 20 et 3 000 caractères!

Votre message doit contenir entre 20 et 3 000 caractères! Merci de consulter vos emails!

Merci de consulter vos emails!